Concrete is a critical material in the construction industry, particularly in Malaysia’s infrastructure projects. However, one common issue that arises during the early stages of construction is early-age thermal cracking. This type of cracking occurs due to temperature variations and other environmental factors, which can compromise the structural integrity of the concrete if not properly managed. This blog will explore the causes, preventive measures, and best practices for mitigating early-age thermal cracking in concrete, particularly in the Malaysian context.

What is Early-Age Thermal Cracking?

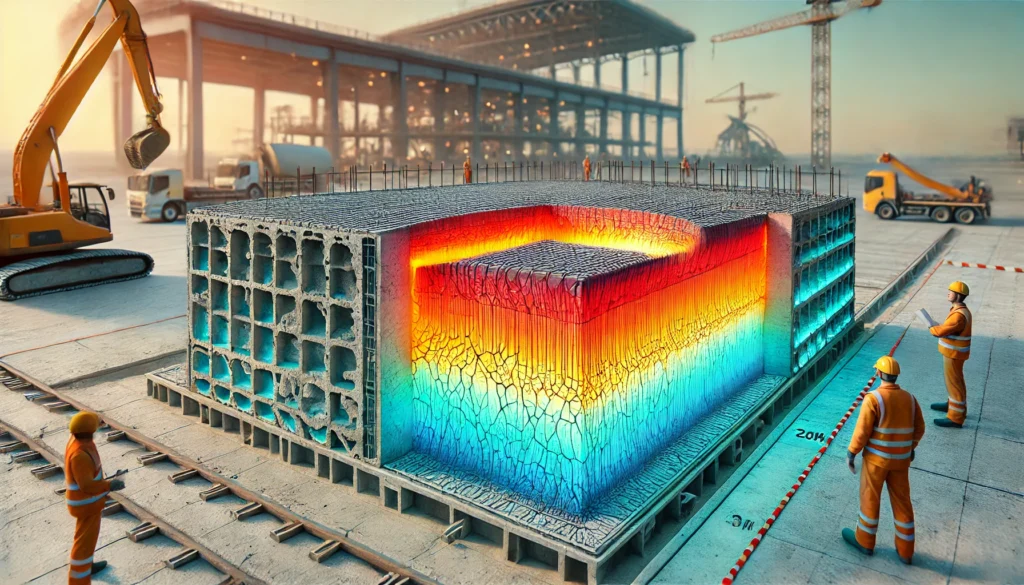

Early-age thermal cracking refers to the formation of cracks in concrete structures that occur shortly after it is poured and set, typically within the first few days. This type of cracking is primarily driven by temperature gradients within the concrete. As concrete cures, it generates heat through the hydration process, known as heat of hydration. This can cause the internal temperature to rise significantly, especially in massive pours like foundations or thick walls. If the temperature drops rapidly (for example, due to cooling weather or exposure to rain), the exterior cools faster than the interior, leading to differential expansion and contraction, which results in cracks.

Causes of Early-Age Thermal Cracking

In Malaysia, where high temperatures and humidity are prevalent, early-age thermal cracking is a significant concern. Several factors contribute to this issue:

- Heat of Hydration: Concrete generates significant heat during the curing process, especially when using high-strength or fast-setting cement. The heat can cause the internal temperature of the concrete to rise, creating a thermal gradient between the core and the surface.

- Rapid Cooling: Sudden temperature changes, often due to rain or cold nights, can cause the surface of the concrete to cool and contract rapidly, leading to cracks.

- Large Structural Elements: Massive concrete elements, such as bridge decks, dams, or building foundations, are more prone to thermal cracking due to their size and the amount of concrete involved. The larger the pour, the greater the thermal differential between the core and the surface.

- Environmental Conditions: Malaysia’s tropical climate, with high humidity, intense sunlight, and occasional heavy rains, can exacerbate thermal variations within concrete structures.

Preventive Measures for Thermal Cracking

Preventing early-age thermal cracking requires a combination of good design practices, proper material selection, and controlled curing conditions. Here are some key preventive measures:

- Using Low-Heat Cement: Opt for cement that generates less heat during the hydration process. Low-heat cement helps to reduce the internal temperature rise within the concrete.

- Gradual Cooling: Apply insulation or use curing methods that allow the concrete to cool gradually rather than experiencing a rapid drop in temperature.

- Controlling the Pour Size: For large pours, divide the structure into smaller sections to reduce the risk of differential temperature. Smaller sections cool more uniformly, minimizing the potential for cracking.

- Proper Curing Techniques: Maintain adequate moisture and temperature levels during curing. In Malaysia, wet curing or the use of curing compounds can help keep the surface moist and prevent rapid cooling.

- Reinforcement and Control Joints: Adding reinforcement or control joints can help control where cracks form, reducing the overall impact of thermal stress.

Case Study: Thermal Cracking in Malaysian Projects

In recent years, Malaysia has seen rapid development in infrastructure, from highways to skyscrapers. Many of these projects have faced challenges related to thermal cracking. A notable example is the construction of large bridges, where the temperature differential between day and night can be significant. Engineers on these projects have implemented various strategies, such as using low-heat cement, adjusting the timing of concrete pours, and applying thermal blankets, to mitigate cracking risks.

Importance of Monitoring and Early Detection

Early detection of thermal cracking is critical for preventing long-term damage to concrete structures. During the curing process, the concrete should be closely monitored using temperature sensors and strain gauges. These tools help track the internal and external temperatures of the concrete, enabling engineers to adjust curing methods as needed to prevent cracks from forming.

Impact on Structural Integrity and Durability

If not properly managed, early-age thermal cracking can lead to several structural issues:

- Reduced Durability: Cracks allow water, chemicals, and other harmful agents to penetrate the concrete, leading to corrosion of the steel reinforcement and weakening the overall structure.

- Aesthetic Issues: Visible cracks can reduce the aesthetic value of exposed concrete surfaces, which is particularly problematic in architectural or decorative structures.

- Increased Maintenance Costs: Repairing cracked concrete can be expensive, especially if the damage is widespread. Preventive measures are far more cost-effective in the long term.

Best Practices for Engineers in Malaysia

- Thermal Control Plans: Develop a comprehensive thermal control plan for each project, particularly when working with massive concrete structures. This plan should include strategies for monitoring temperature, controlling pour sizes, and managing environmental conditions.

- Selection of Materials: Choose cement types and admixtures that are suitable for Malaysia’s tropical climate. Use low-heat cement and consider the use of supplementary cementitious materials (SCMs), such as fly ash or slag, to reduce the heat of hydration.

- Pre-Pour Planning: Coordinate the timing of pours to avoid the hottest parts of the day and to minimize the exposure of fresh concrete to sudden environmental changes.

- Post-Pour Monitoring: Employ advanced monitoring techniques to detect any potential for cracking during the curing process. Sensors embedded in the concrete can provide real-time data on temperature variations and stress levels.

Conclusion

Early-age thermal cracking is a common but preventable issue in concrete construction, particularly in the tropical climate of Malaysia. By understanding the causes and implementing preventive measures, such as using low-heat cement, applying proper curing techniques, and monitoring temperature variations, engineers can reduce the risk of cracking and ensure the longevity and durability of concrete structures.

FAQ About Thermal Cracks

Thermal Cracks Meaning

Thermal cracks refer to cracks that form in materials like concrete due to temperature changes. They occur when temperature variations cause expansion and contraction within the material, leading to stress that results in cracking.

Thermal Cracks in Concrete

Thermal cracks in concrete are a result of temperature differences within the concrete mass, often due to the heat of hydration. When the surface cools faster than the interior, differential stresses cause the surface to crack.

How to Repair Thermal Cracks in Concrete

Repairing thermal cracks in concrete typically involves using crack fillers, epoxy injections, or cement-based repair materials to restore the structural integrity. In severe cases, additional reinforcement or surface overlays may be necessary.

Thermal Cracks in Walls

Thermal cracks in walls occur due to temperature fluctuations that cause building materials like concrete, brick, or plaster to expand and contract. This is common in both exterior and interior walls, particularly in regions with extreme weather conditions.

What Causes Thermal Cracks

Thermal cracks are primarily caused by temperature changes, which induce expansion and contraction in materials. In concrete, the heat of hydration or sudden weather changes can create temperature differentials that lead to cracks.

Thermal Cracks in Brickwork

In brickwork, thermal cracks occur when the bricks or mortar expand and contract due to temperature changes. Over time, this stress can cause cracks to form along mortar joints or in the bricks themselves, compromising the integrity of the structure.