Thermographic inspection has emerged as a crucial tool for civil engineers, especially in detecting structural anomalies in buildings, bridges, and other infrastructure. By leveraging thermal imaging, engineers can detect variations in temperature across surfaces, allowing them to uncover hidden issues that might otherwise go unnoticed. In this blog, we’ll explore the importance of thermographic inspections, their principles, applications, and the role they play in ensuring the safety and longevity of civil structures.

What is Thermographic Inspection?

Thermographic inspection, often referred to as infrared thermography, is a non-invasive method used to detect temperature variations on the surface of objects or structures. By using thermal cameras, inspectors can visualize and measure heat emitted from various objects, including building materials, to identify potential anomalies.

This inspection method is highly effective in detecting issues such as insulation defects, moisture intrusion, electrical problems, and structural cracks. The technology works on the principle that most objects emit infrared radiation as a function of their temperature, and any deviations from the norm can indicate an underlying problem.

How Thermographic Inspection Works

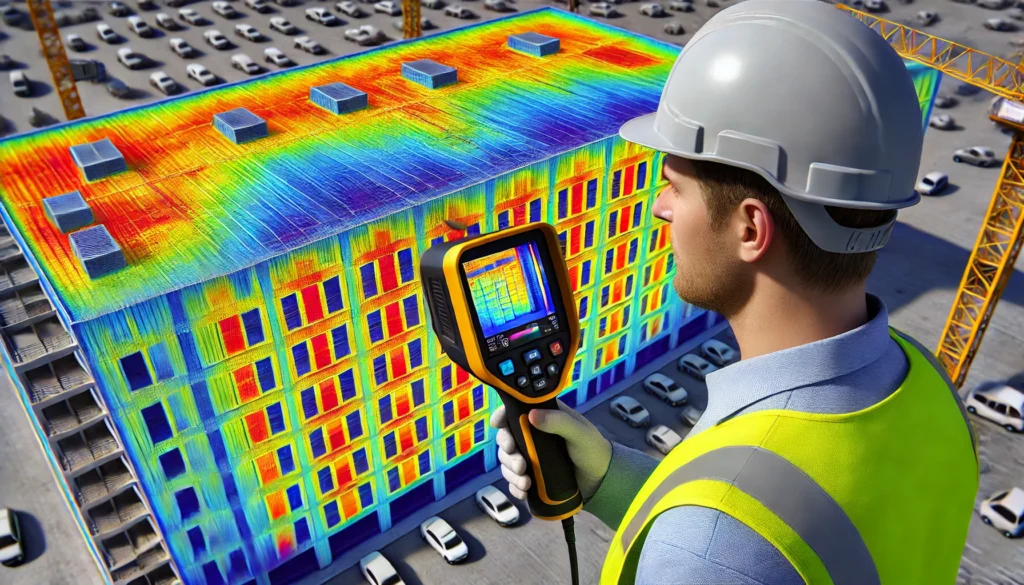

At its core, thermography relies on the concept that all objects emit infrared radiation based on their temperature. When a thermal camera is used, it detects the infrared radiation and produces a thermal image or heat map of the inspected area. Variations in temperature appear as different colors on the thermal image, making it easier to spot irregularities.

For civil engineers, thermographic inspections are particularly useful because they provide a quick and efficient way to inspect large areas without the need for invasive procedures. These inspections can be done from a distance and are effective even in challenging environments, making them ideal for inspecting tall buildings, bridges, and industrial facilities.

Applications of Thermographic Inspection in Civil Engineering

Thermographic inspection has a broad range of applications in civil engineering, particularly in the maintenance and assessment of structures. Some key applications include:

1. Building Envelope Inspections

In building envelope inspections, thermography is used to assess the thermal performance of walls, windows, and roofs. It helps in identifying areas where insulation may be compromised, leading to energy loss. Detecting these problems early allows for corrective action, improving the energy efficiency and comfort of buildings.

2. Moisture Detection

Water infiltration can cause significant damage to structures if not detected and addressed early. Thermography is a highly effective tool for identifying moisture issues, as wet areas tend to have a different thermal signature than dry areas. By pinpointing areas of moisture intrusion, engineers can take steps to prevent further structural damage.

3. Electrical Inspections

In industrial and commercial settings, thermographic inspections are often used to inspect electrical systems. Overheated components such as circuit breakers, transformers, and switchgear can be detected using infrared thermography. Identifying these issues early can prevent costly equipment failures and reduce the risk of electrical fires.

4. Roof Inspections

Flat roofs are particularly prone to water damage, and thermographic inspection is a valuable tool for detecting areas where water may have infiltrated the roof membrane. By identifying these areas, repairs can be made before more extensive damage occurs.

5. Concrete and Structural Assessments

Thermographic inspection can also be applied in detecting voids, delamination, and other defects in concrete structures. This is particularly useful in the assessment of bridges, roads, and other critical infrastructure, where timely repairs are essential to maintaining safety and performance.

Advantages of Thermographic Inspection

Thermographic inspections offer several advantages that make them an attractive choice for civil engineers:

- Non-Destructive: Thermographic inspection does not require any physical contact with the structure, making it a non-invasive method for detecting anomalies.

- Real-Time Results: The thermal images produced by infrared cameras provide real-time information, allowing inspectors to identify issues immediately.

- Efficiency: Large areas can be inspected quickly, which reduces the time and labor costs associated with traditional inspection methods.

- Versatility: Thermography can be used in a wide range of conditions, including during day or night, and in various weather conditions.

- Preventative Maintenance: By detecting problems early, thermographic inspections can help prevent more serious issues from developing, saving both time and money in the long term.

The Science Behind Thermographic Inspection

Thermographic inspection is based on the principle that all objects emit infrared radiation relative to their temperature. The thermal imaging camera detects this radiation and converts it into a visible image. In the case of structural inspections, abnormal temperature variations can indicate potential problems, such as moisture penetration, poor insulation, or even cracks in structural materials.

Thermal cameras measure the amount of infrared radiation emitted by objects and translate it into a heat map, where different temperatures are represented by different colors. Typically, warmer areas appear in shades of red, orange, and yellow, while cooler areas are shown in blue and green.

In building inspections, areas with poor insulation, for example, will appear warmer (because more heat is escaping), whereas moisture-laden areas may appear cooler than the surrounding dry areas. This contrast allows inspectors to identify areas of concern without the need for intrusive measures such as drilling or dismantling parts of the structure.

The Importance of Thermographic Inspections for Civil Engineers

For civil engineers, thermographic inspection is a powerful diagnostic tool that enhances the ability to maintain and assess the condition of structures. It allows engineers to detect issues that may not be visible to the naked eye, such as hidden moisture, structural defects, or compromised insulation. By identifying these issues early, engineers can take proactive steps to mitigate potential problems, ensuring the longevity and safety of the structure.

Furthermore, thermography is particularly useful in the context of energy efficiency. Building envelopes that are poorly insulated can lead to significant energy losses, which can be costly for building owners. By identifying and addressing these inefficiencies through thermographic inspection, energy consumption can be reduced, leading to lower utility bills and a smaller environmental footprint.

Thermographic Inspection in Structural Health Monitoring

Thermography plays a crucial role in structural health monitoring, particularly for aging infrastructure. As bridges, roads, and other structures age, the risk of defects increases. Regular thermographic inspections can help civil engineers monitor the condition of these structures, identify any emerging issues, and ensure that maintenance and repair work is carried out in a timely manner.

Conclusion

Thermographic inspection has become an invaluable tool for civil engineers in detecting structural anomalies and ensuring the safety and efficiency of buildings and infrastructure. By utilizing thermal imaging technology, engineers can identify hidden problems such as moisture infiltration, insulation deficiencies, and electrical issues, often before they become visible or cause significant damage. This non-invasive, real-time inspection method offers an efficient and cost-effective way to maintain the structural integrity of civil assets.

By incorporating thermographic inspections into routine maintenance plans, civil engineers can help prolong the life of structures, reduce energy consumption, and prevent costly repairs.

FAQ

What is thermographic NDT?

Thermographic Non-Destructive Testing (NDT) is a method of inspecting materials or structures without causing damage. It uses thermal imaging to detect defects or anomalies by measuring surface temperature variations.

What is a thermal imaging inspection?

A thermal imaging inspection involves using an infrared camera to detect temperature differences on the surface of an object or structure. These temperature variations can indicate issues such as moisture intrusion, insulation problems, or electrical faults.

What is thermographic screening?

Thermographic screening is the process of using thermal imaging technology to quickly scan and detect temperature anomalies across a surface, which may indicate underlying issues like structural damage or material defects.

What is the purpose of a thermographic survey?

The purpose of a thermographic survey is to identify temperature variations across the surface of a structure. These variations can reveal issues such as moisture, air leaks, or insulation problems, allowing for timely repairs and maintenance.

What is the principle of thermographic inspection?

The principle of thermographic inspection is based on the fact that all objects emit infrared radiation relative to their temperature. A thermal camera detects this radiation and produces a thermal image, where temperature variations can indicate potential structural issues.

What is the purpose of thermographic scanning?

The purpose of thermographic scanning is to detect and diagnose potential problems in structures or materials by identifying temperature anomalies. This method is non-invasive and helps in maintaining structural integrity and energy efficiency.

References: