Concrete is the backbone of construction, but it is also complex chemistry. When concrete fails to achieve its required strength, shows signs of early deterioration, or exhibits severe defects like honeycombing, standard engineering knowledge is often insufficient. At Pro Inspect Solution, we provide specialized Concrete Technology Consultancy. We go beyond visual inspection, utilizing scientific methods and forensic investigation to diagnose root causes, audit production quality at the source (batching plants), and provide actionable solutions for flawed concrete structures.

1. Ready-Mix Concrete (RMC) Batching Plant Audit Quality concrete starts at the source. We conduct independent Technical Audits of RMC plants on behalf of developers and main contractors to ensure compliance with MS EN 206 and CIS 21.

What We Audit:

Calibration Checks: Verifying the accuracy of weighing scales for cement, aggregates, and water.

Material Storage: Inspecting aggregate stockpiles for contamination and cement silos for moisture control.

QA/QC Processes: Reviewing their internal testing records and mix design controls.

Benefit: Ensures you are getting the quality you pay for and reduces the risk of receiving non-compliant concrete on site.

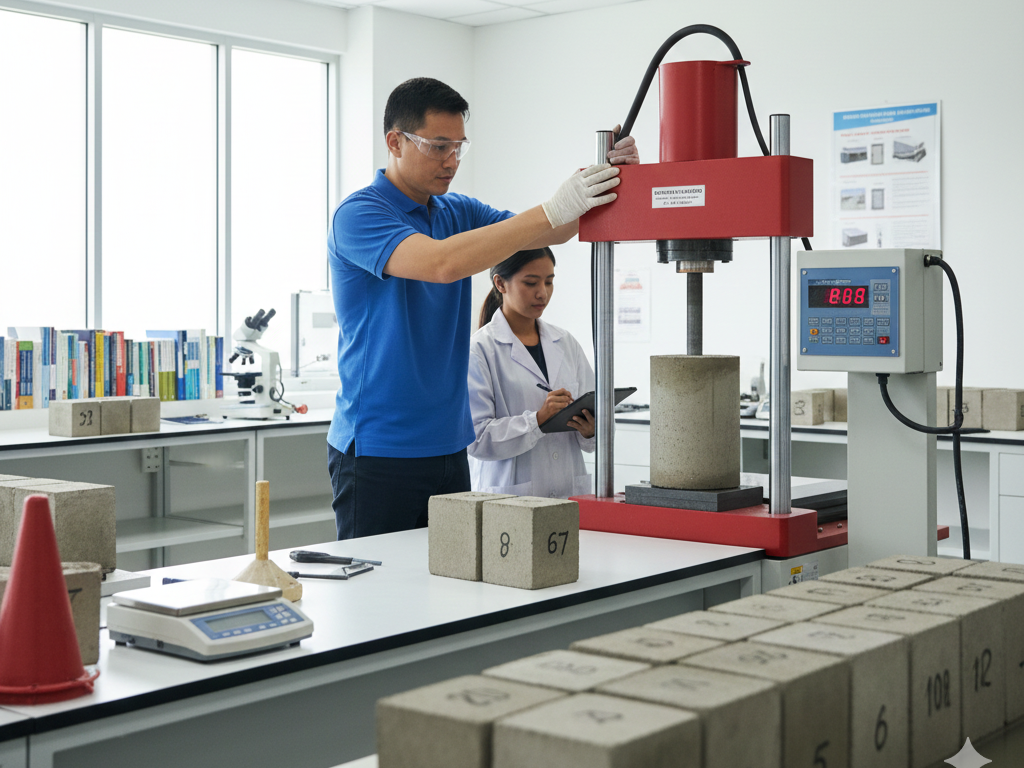

2. Concrete Forensic Investigation & NDT When concrete appears defective, we use Non-Destructive Testing (NDT) to assess its actual condition without damaging the structure.

Rebound Hammer Test: For surface hardness estimation.

Ultrasonic Pulse Velocity (UPV): To check for internal voids, cracks, and uniformity.

Cover Meter Survey: To locate rebar depth and size.

Concrete Coring (Semi-Destructive): Extracting samples for laboratory compressive strength testing.

3. Mix Design Review & Optimization We review proposed concrete mix designs before construction begins to ensure they are suitable for the specific project environment (e.g., marine environments, high-rise pumping). We look at water-cement ratios, admixture dosage, and aggregate grading.

General contractors and even general structural engineers may lack the deep knowledge of material science required to solve complex concrete problems. You need a specialist when:

Concrete Cubes Fail: Your 28-day cube test results are below the required design strength, and you need to prove the in-situ structure is safe.

Supplier Disputes: You suspect the Ready-Mix Concrete (RMC) supplier provided substandard material, but need technical proof.

Recurring Defects: You are seeing repeated issues like segregation, bleeding, or plastic shrinkage cracks on site.

When in-situ concrete doesn't meet design requirements.

Poor consolidation leaving voids around reinforcements.

Issues in mass concrete pours due to high heat of hydration.

Our approach is data-driven.

Visual mapping of defects and propose suitable testings i.e., NDT or coring methods.

Partnering with accredited labs for chemical and physical testing.

Providing a conclusive report on the cause of failure and recommending remedial actions.

Get scientific answers to your concrete problems. Contact our technical specialists today.

Your one-stop engineering partner for Building Inspection, Dilapidation Survey, Concrete Assessment and Dispute Resolution. From advanced Drone & LiDAR surveys to Expert Witness services, we secure your property’s value and safety.

Copyright © 2026 Pro Inspect Solution (M) Sdn Bhd. All Rights Reserved.