Structural Health Monitoring (SHM) has become an essential component of maintaining the safety, longevity, and integrity of buildings and infrastructure. From bridges and tunnels to residential and commercial buildings, SHM ensures that these structures remain functional and safe over time by identifying potential risks before they escalate into costly or dangerous failures.

In this comprehensive guide, we will dive deep into the concept of Structural Health Monitoring, its stages, various techniques, and how it differs from condition monitoring. We’ll also explore how Pro Inspect Solution provides exceptional services in Malaysia in this field, including their approach to SHM and structural assessments.

By the end of this post, you’ll have a full understanding of SHM, including the stages involved and its significant role in infrastructure safety.

What is Structural Health Monitoring (SHM)?

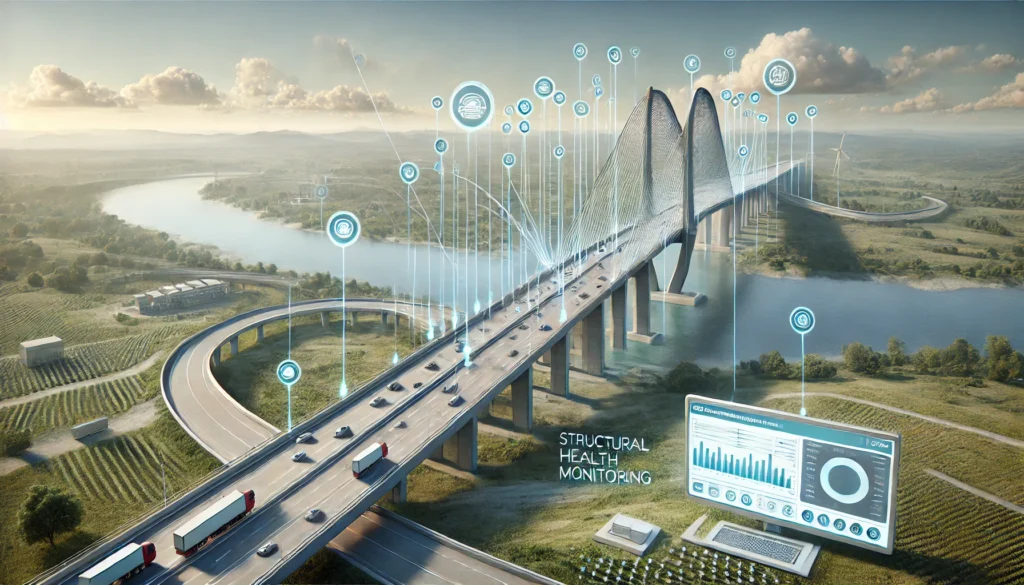

Structural Health Monitoring (SHM) is the process of implementing a damage detection strategy for infrastructures, such as bridges, buildings, or tunnels. The primary objective of SHM is to monitor the health and stability of a structure by collecting data through sensors and other technologies to detect damage or degradation over time.

SHM ensures continuous observation and evaluation of a structure’s condition, allowing for timely interventions to maintain its integrity. This process plays a crucial role in minimizing risks, improving safety, and optimizing the operational life of a structure by providing early warning signs of potential failures.

Benefits of SHM

- Increased Safety: Early detection of issues like cracks or fatigue can prevent catastrophic failure.

- Cost Savings: SHM reduces the need for expensive manual inspections and repairs by catching problems early.

- Extended Lifespan: Consistent monitoring can extend the useful life of the structure by ensuring timely maintenance and repairs.

Industries Utilizing SHM

SHM is widely applied in industries such as:

- Civil Engineering (bridges, tunnels, buildings)

- Aerospace (aircraft integrity)

- Marine Engineering (ships and oil rigs)

- Automotive (structural monitoring of vehicles)

Stages of Structural Health Monitoring

Understanding the stages of SHM is crucial for implementing an effective monitoring system. SHM typically follows a systematic process, ensuring that all potential issues are identified and addressed.

1. Operational Evaluation

The first stage involves understanding the structure’s purpose, environment, and performance requirements. This includes identifying factors such as environmental stressors (wind, temperature changes, vibrations), historical performance, and the type of loads the structure must withstand.

2. Data Acquisition

In this stage, sensors are strategically placed on the structure to collect data. These sensors may track factors such as stress, strain, temperature, and vibrations over time. Data is collected continuously or at specific intervals to provide insight into the structure’s condition.

3. Data Processing

The raw data gathered from sensors must be processed and interpreted. Data processing algorithms are applied to filter noise, extract relevant features, and detect anomalies that could indicate structural issues.

4. Condition Assessment

In the final stage, the processed data is analyzed to determine the structure’s current condition. This may involve comparing the data against a baseline or using statistical models to predict future deterioration.

Structural Health Monitoring Techniques

Several techniques can be used in SHM, each suited to different types of structures and monitoring needs. Below are some of the most commonly used methods:

1. Vibration-Based Monitoring

This technique monitors changes in a structure’s vibrational characteristics. A change in vibration frequency can indicate the presence of damage, such as cracks or weakening materials. It is widely used for bridges, buildings, and other large structures.

2. Acoustic Emission Monitoring

Acoustic emissions are sound waves generated by the release of energy within a material, typically caused by crack growth or other types of damage. Monitoring these emissions helps detect the early formation of fractures or defects.

3. Fiber Optic Sensors

Fiber optic sensors provide high-resolution data and are often used in real-time monitoring applications. These sensors measure strain, temperature, and other critical parameters, making them useful for applications where precise monitoring is required.

4. Ultrasonic Testing

Ultrasonic waves are used to detect internal flaws in a structure. This non-destructive testing method is effective at identifying hidden cracks, voids, and other defects that may not be visible externally.

5. Thermography

Thermal cameras are used to detect variations in temperature that may be caused by structural defects or stress. This technique is particularly useful for monitoring buildings and bridges in real-time, as it can detect energy losses or potential weaknesses.

Condition Monitoring vs. Structural Health Monitoring

While both Condition Monitoring and Structural Health Monitoring (SHM) involve the tracking of a system’s health, there are key differences between the two.

- Condition Monitoring: Primarily focused on machinery and equipment, condition monitoring tracks parameters such as vibration, temperature, and pressure to identify potential mechanical failures.

- Structural Health Monitoring (SHM): Focuses on civil and mechanical structures such as bridges, buildings, or vehicles. SHM involves the use of sensors to monitor the health of a structure over time, primarily to identify degradation or damage.

While condition monitoring is typically applied to mechanical systems, SHM is more concerned with static or semi-static structures.

The Role of Pro Inspect Solution in Structural Health Monitoring

About Pro Inspect Solution

Pro Inspect Solution is a leading provider of structural inspections and assessments in Malaysia. They specialize in a range of services, including Structural Health Monitoring (SHM), offering advanced monitoring systems to ensure the safety and longevity of buildings, bridges, and other structures.

Pro Inspect Solution utilizes cutting-edge technology to deliver reliable and timely assessments. Their team of highly skilled engineers and inspectors works closely with clients to ensure that structures meet the required safety and regulatory standards.

Services Offered by Pro Inspect Solution

- Building and Structural Inspections: Comprehensive evaluations to detect potential structural weaknesses or damages.

- SHM Solutions: Implementation of sensor-based monitoring systems that continuously track structural health in real-time.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing and thermography to identify hidden flaws without causing damage to the structure.

- Structural Assessment and Reporting: Detailed reports and recommendations for repairs or maintenance based on inspection and monitoring results.

Pro Inspect Solution stands out due to its commitment to excellence and innovative approach to structural assessment. They utilize a combination of traditional inspection methods and modern SHM techniques to ensure that structures are safe, compliant, and built to last.

FAQs about Structural Health Monitoring

What is meant by structural health monitoring?

Structural Health Monitoring (SHM) refers to the process of using various techniques and sensors to collect data about the physical condition of a structure, such as a building, bridge, or tunnel. This data is then analyzed to assess the structure’s health, detect potential damages, and predict future degradation.

What are the structural health monitoring stages?

The stages of structural health monitoring include:

- Operational Evaluation: Understanding the structure and its environment.

- Data Acquisition: Collecting data using sensors.

- Data Processing: Filtering and analyzing the collected data.

- Condition Assessment: Determining the health of the structure based on data analysis.

What are the structural monitoring techniques?

Several SHM techniques include:

- Vibration-Based Monitoring

- Acoustic Emission Monitoring

- Fiber Optic Sensors

- Ultrasonic Testing

- Thermography

Each of these techniques is suited to specific structural monitoring needs and offers varying levels of precision and data collection.

What is the difference between condition monitoring and structural health monitoring?

The key difference is that condition monitoring focuses on mechanical systems and equipment, while SHM is concerned with civil structures like buildings and bridges. Condition monitoring aims to prevent mechanical failure, whereas SHM monitors the overall health and integrity of a structure to detect physical damage.

What are the 4 basic steps to monitoring?

The four basic steps in SHM include:

- Operational Evaluation: Define the structure and environmental factors.

- Data Acquisition: Collect sensor data.

- Data Processing: Analyze and filter data for insights.

- Condition Assessment: Evaluate the structure’s health and potential risks.

What are the 4 health monitoring tests?

The four primary SHM tests typically involve:

- Vibration Analysis: Monitoring for changes in vibrational frequency that could indicate damage.

- Acoustic Emission Testing: Detecting sound waves caused by internal damages like crack formation.

- Ultrasonic Testing: Using high-frequency sound waves to detect hidden flaws.

- Thermal Imaging: Identifying temperature variations that may point to structural weaknesses.

Conclusion

Structural Health Monitoring (SHM) is an indispensable process for ensuring the safety and durability of infrastructures such as buildings, bridges, and tunnels. By continuously assessing the health of these structures, SHM helps prevent catastrophic failures, reduces repair costs, and extends the lifespan of the infrastructure.

Pro Inspect Solution, based in Malaysia, offers top-notch SHM services, ensuring that buildings and other structures maintain their structural integrity over time. With advanced techniques like real-time monitoring, non-destructive testing, and comprehensive inspections, they help safeguard Malaysia’s critical infrastructure.

Reference Links:

- MDPI Journal

- IIETA Journal